Projects & Case Studies

Applied Research Projects

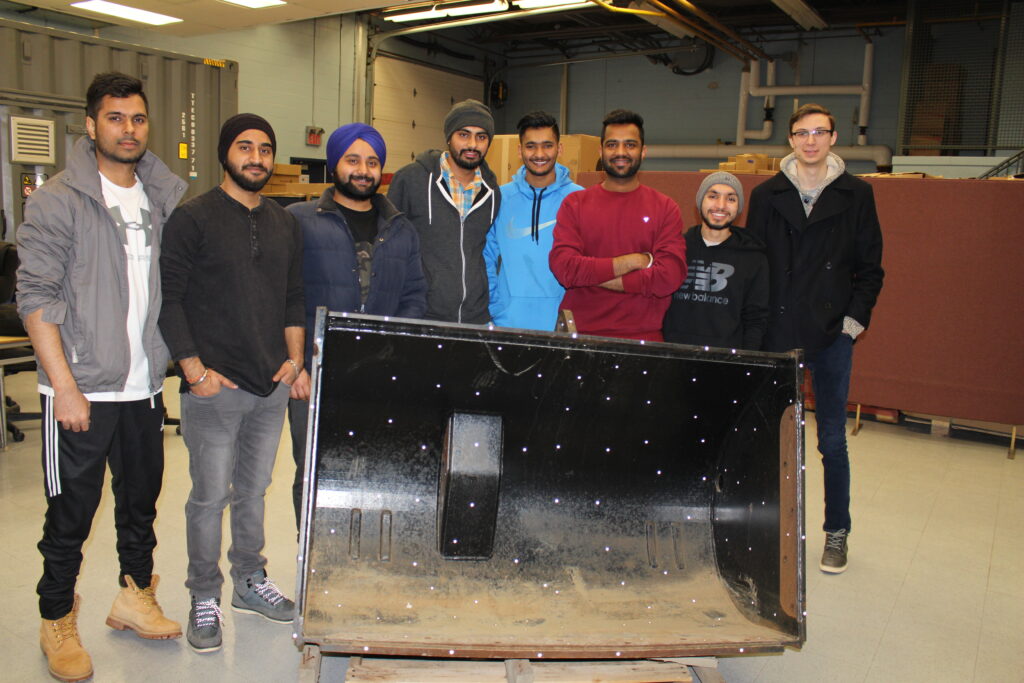

Earthmoving Bucket Tooth

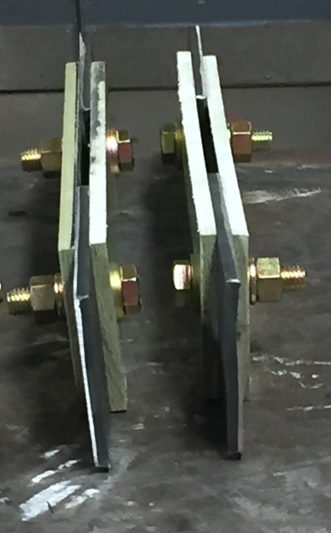

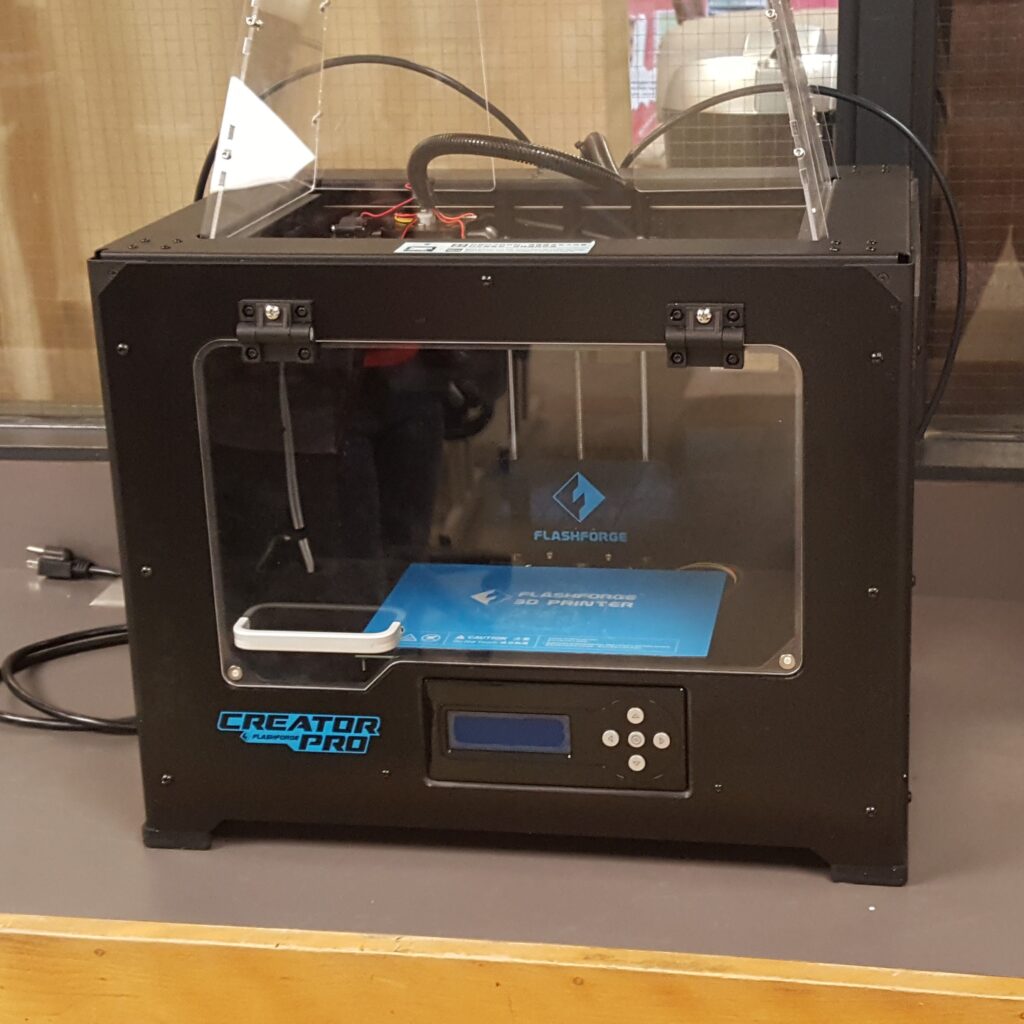

Northern College’s Innovation Hub recently completed the 3D print of a bucket tooth for the local Timmins company Bucket Shop. The Bucket Shop repairs and produces cast lip and heal assemblies while also offering industry and businesses innovative designs to improve effectivity. Knowing about the Innovation Hub’s ability to 3D print a variety of items for businesses and industries, the Bucket Shop requested the Innovation’s Hub assistance in printing their prototype. This 3D print project, which was led by the AREI’s research officer, Keith Delaurier, was a prototype intended to showcase the new change of design for earthmoving buckets. The conceptualized prototype greatly improves productivity for industry and businesses throughout the field.

Based upon a conceptualized model conceived by Metalogenia (MTG), the Innovation Hub printed the model by using Markforged Mark II printer using Precision PLA. This took place in our 3D printing lab, which features numerous 3D printers with varying capabilities. Unlike a steel model, the printed design was advantageous because it offered a genuine presentation of the new model, which could be easily transported to various conferences for showcase. The 3D printed model also easily enables individuals to inspect and handle the prototype. In fact, the Bucket Shop brought the bucket tooth model to the 2022 Central Canada Resource Expo in Thunder Bay as part of the conference’s objective to highlight advancements in resource technologies. The light weight of the prototype enabled easy transportation in flight. Accordingly, this 3D printing capacity at the Innovation Hub is beneficial to all companies and industries across Northern Ontario.

Following the success of the print, the model will go into production for subsequent use for companies and industries that depend upon innovative earthmoving technology, especially as it relates to resource extraction. Accordingly, the Innovation Hub’s contribution supported the Bucket Shop’s invention and encouraged the economic growth across the region. The Bucket Shop was very pleased with the success of the project and the appeal it had to conference attendees. As part of this success, the Bucket Shop and the Innovation Hub will be moving forward on more projects in the future. As part of the Innovation Hub’s ability to provide this support across the Northern Ontario region, the Innovation Hub plans to expand its 3D printing infrastructure to more greatly contribute to communities, businesses, and industries.

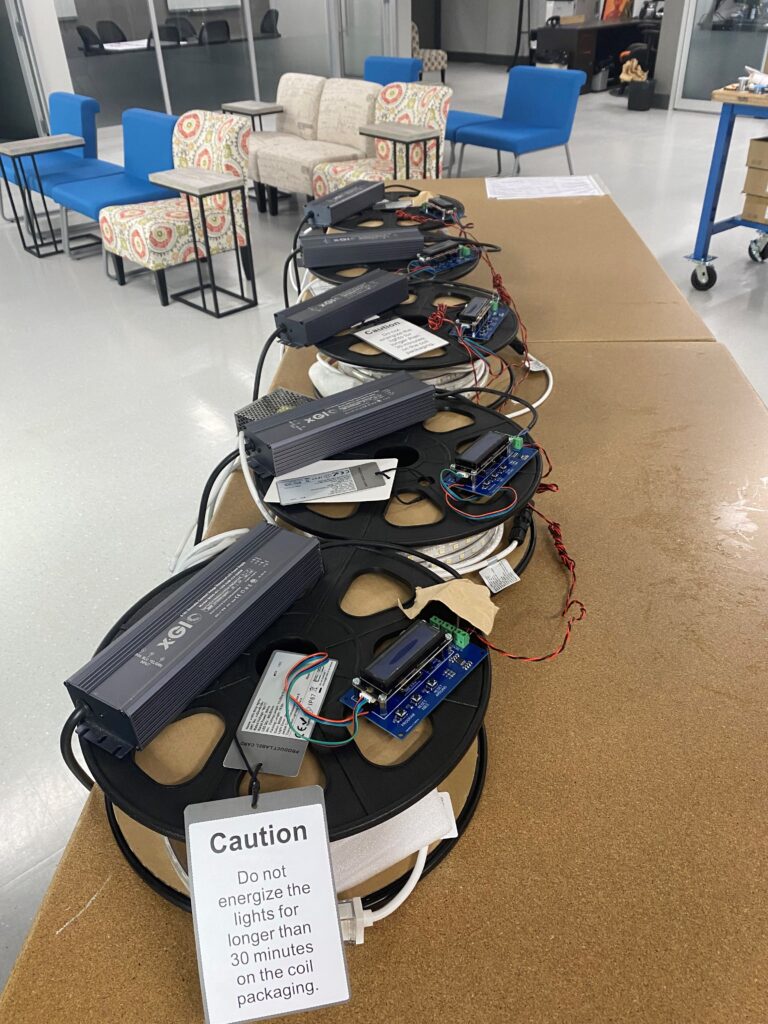

X-Glo Lighting Product Development

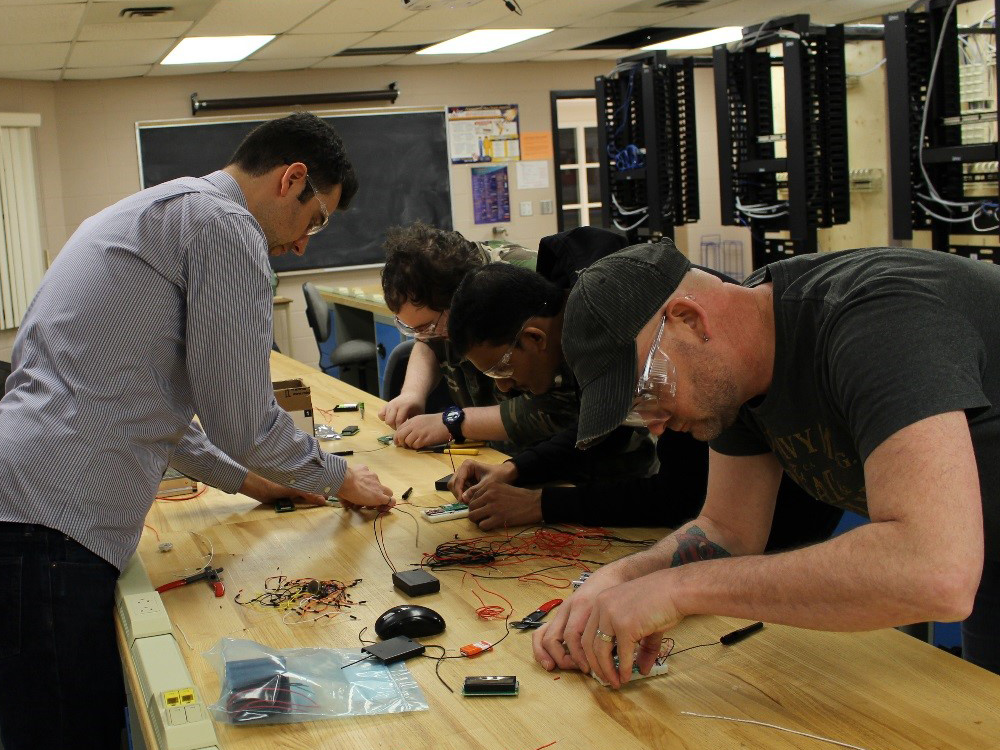

X-Glo requested us to develop a control system that would control the luminance of their LED light strips within 100 meters of a mining tunnel entry/exit. Inadequate lighting at the tunnel entry/exits statistically increases the chances of accidents around these areas. As a result of the teamwork of faculty, a student and a AREI research officer, Northern College have developed electronics, software, the enclosure (3D printed) and the telecommunications for an innovative variable lighting system for the entrance to underground mines.

Underground Communication Network

Northern College Electrical students created a wireless and self-healing ZigBee (an off-the-shelf transceiver module) mesh network to be used for underground communications. The prototypes were tested underground for coverage, spacing, and the maintaining of connection.

Scanning Technology in Mining Supplier Services

Mining supply companies are looking to add 3D scanning capabilities to their suite of offerings. The 3D scanner will be used as a technology tool to do the work that now uses human resources, resulting in significant accuracy improvements and the precision required to create drawings and products with structural integrity.

Entrepreneurial Success Stories

Mine Safety Solutions

Mine Safety Solutions is dedicated to creating innovative safety equipment for use in the mining and industrial fields. Its goal is to help mining and industry organizations achieve the highest of safety standards in the workplace, thereby reducing the number and severity of workplace injuries and protecting the well-beings of workers in Canada and beyond. While MSS focuses primarily on the mining industry, its products and services impact other sectors, including construction, manufacturing, mechanical, and many more.

Handy Hydrant

Handy Hydrant is very easy to transport and handle. For instance, if we have rural areas to go to, it comes with a pack so the other fellows can take the pump and hoses… it is very easy to setup and adapts to the uneven grounds. Where there are no hydrants, Firefighters are forced to fill a portable pool; a process that wastes precious time and manpower. Until now! The Handy Hydrant is easy to use, third party tested and effective! And what started out as a tool for firefighters has evolved into a watering system that is used in agriculture, industry and commercial settings.